MCP Water Jet Service

What is a Waterjet cutter?

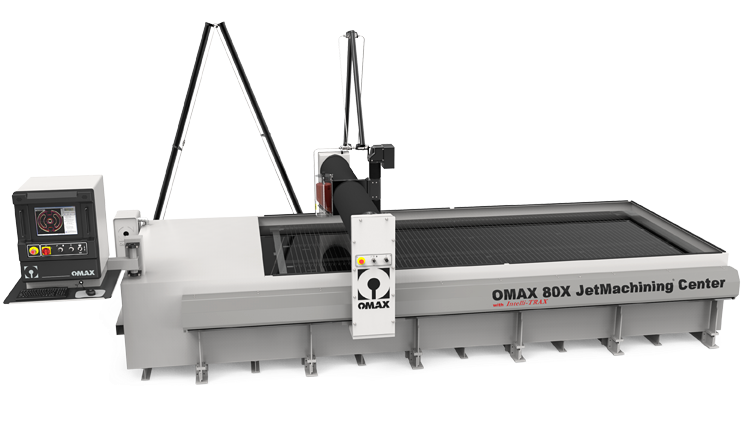

OMAX 80X Series - Precision Jet Machining Center

A waterjet utilizes a high pressure stream of water to erode a narrow line in the stock material. To cut a wider range of materials from tool steel to titanium to foam, a granular (typically garnet) abrasive is added to the waterjet, increasing the cutting power. Because the abrasive is added at the nozzle, it is simple to switch between water only and abrasive waterjet cutting. This flexibility greatly enhances the versatility of a waterjet machine, as it can easily switch from cutting ½" (1.27cm) foam gaskets to 4" (10.16cm) titanium brackets. Whatever material you need cut MCP has it covered at the precision you demand.

What materials can a waterjet cut? It's easier to answer what materials can't be cut with a waterjet. An abrasive waterjet can cut virtually anything, but we don't recommend cutting tempered. Waterjet can cut aluminum, brass, bronze, carbon fiber composite, ceramic, copper, fiberglass, glass, granite, Kevlar, marble, Plastic, stainless steel, titanium, tungsten and a lot more.

What industries use waterjet cutters? From jewelry making to aerospace, waterjets are involved in the production of many products you may not expect. Due to the versatility of cutting with abrasive and the ease-of-use software, OMAX brand waterjets are in a wide variety of industries including; education, food processing, metal service and fabrication shops.

Our waterjet cutting services offer a cost-effective and on-demand solution for your manufacturing needs. Call or email to get an instant quote on high quality waterjet machined parts for virtually any job.

Create Your Multi-Craft Plastics Website Account!

Thank you to all our Veterans

Thank you to all our Veterans